| A Ducati Restoration - Well Maybe ! |

|

It was early July 1983. Pittsburgh was having the usual heat wave. My auto restoration shop was in-between jobs. My long-time racing friend was answering the phone and painting his mom's car, so Phyllis and I left for the Bahamas. We were staying at the newly opened Coral World resort near Nassau while our Bahamian attorney's wife flew to Eleuthera to surreptitiously empty the joint bank account we shared with our negligent 'partner' in the retail ice business. Our partner was not fairly dividing all the profits from a commercial ice machine that we had imported and installed in his hotel/bar on this very skinny and very long out-island. All this was not in strict accordance with Bahamian statutes, mind you, but if you can't trust a criminal, whom can you trust? While our proxy was busy cashing-out at the Governor's Harbor branch of Barclay's Bank, we were enjoying our bayside room-with-a-view and private pool (paying the off-season 'travel-agent' rate), driving intoxicated on the left side of the roads, and generally stuffing ourselves on prawns and conch in Nassau. It was not exactly a nerve racking wait for our money, and the international phone service was such that my in-laws couldn't call us twice a day to make sure we hadn't drowned or been murdered. Neither could my racing friend. John's birthday and mine are a day apart, July 8 for me, 7 for him. We had reminisced for years now over all the fun we had in the early '60s with a very trick Goldstar he had built, and I had piloted and mostly paid for. Boy, if we could only do it again with what we know now! Well when Phyl' and I got home, John invited us over to his place to see the birthday present he got himself, and not incidentally, the one he got for me. This would be a Norton Dominator 99 (don't worry, he only needed it for the frame), and for me, a Ducati 750 twin (don't worry, it'll make a great roadracer). It was too good a deal, that had to be negotiated in a very timely manner, cash, of course, so he simply borrowed a few thou, in my name, from my shop landlord! I was, ah, quite surprised.

A 1974 750GT, plenty of potential, and John already had Syd Tunstall's latest catalog with all the goodies I might need. He also had Cosmopolitan's catalog opened to all the goodies he might need. It wasn't just an offer I couldn't refuse; it was a done deal. But wait, there's more! I was shown fresh sketches for all the bodywork he envisioned for his 'new' Norton-framed Goldstar, including a half-fairing that would also look nice on my 'new' Duc. In for a dime…, in for how much? Well, the Third World ice monopoly had been good to me, and it was looking to be good for Syd as well. John had found new purpose in his life, and, oh by the way, another new catalog: Aircraft Spruce & Specialty, purveyors of Fiberglas, Kevlar and carbon-fiber. In for how much…? Never mind! He set about crafting masters, then molds, swapping Norton parts for Goldstar goodies, and trading up, down and sideways for big brakes. All the time, encouraging me to do something, anything, with the GT:

I got as far as mocking-up a bike with Syd's glass and Cosmo's Grimeca 4LS when tragedy struck. John's fragile heart left him, and he died on the eve of my birthday. I was so overwhelmed that it would be five years before I could return to either the Featherbed Goldstar or the café Duc., both works-of-love in progress. When I finally assembled all the parts I could find for the F/Gs, the magic began to take shape: The Grimeca had been up-traded to front and rear Yamaha TZs, the RoadHolders had turned into Cerianis, the frame had a trick swing arm and exhaust, and all the bodywork was finished in Kevlar and carbon (shh!).

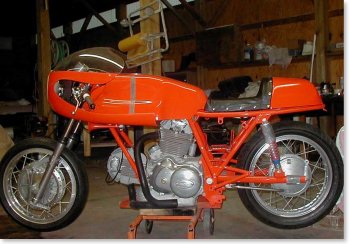

I took another look at the Duc and the not so small pile of parts that might fit on it. This would have to be resurrected as a roadracer, not just a café 'cutie'. I began by doing what I do best: take things apart. I stripped everything to the bare frame, cleaned and examined all the parts, and continued with what I like most: paint! Starting with a quart of 'Farina red' (Isn't farina white? No, it's a man not a cereal, you young parts-person.), I painted the frame and began fitting the body parts first. Now for the real fun:

John's choice of a GT model seemed to be very wise. The mileage was low, only 8512, and mechanical wear was almost non-existent. No visible wear on either of the sprockets, and the chain, fully extended, would only bend about two inches. The sides of the carb slides were barely polished. The only engine covers that had ever been removed were for the tappets. The valve lashes were in adjustment, and looking down the ports, the valve heads looked new. The previous owner (only one) did not believe in using a front brake, ever, and the rear shoes were only moderately worn, with the drum looking perfect. The ignition points had never been adjusted and the gaps were still in spec. Much better than I had a right to expect! I re-laced both wheels for a start. The rims needed a little buffing, and I wanted all the spokes to be at the same tension. I like to do this by plucking them for equal pitch while the wheel is being trued. Next came the Comp-Ks. Trial fits for all the bodywork was next and the mounting points were easily located (thank you, Syd). I wet-sanded all the gel coats, which were free of imperfection (thank you again, Syd), and loaded up the spray gun. I must say that watching freshly applied, catalyzed enamel gloss-over is almost as satisfying as…, well, you know. Once the paint had a few days to harden, the end product took shape:

Not too shabby! A cute feature about reconstructing a bike for racing is that one only puts back things that are involved in getting down the road and coming to a stop. Minimalism is the order of the day. Parts that are never installed are parts that never fail! Turn signals? We don't think so. One headlight will do the job, and since right-handers predominate on a track, a left-hand offset provides the most height on most corners.

Oh, that beautiful fairing. It was John's philosophy that streamlining must control turbulence, direct cooling air and fit the rider like a 'suit of clothes'. The rear edges of the screen are shaped to fit flush with the tops of my shoulders when my chin is on the tank. The bottom of the fairing is reverse curved just above the tire and extends from the outsides to the top frame tubes in order to keep air flowing as smoothly as possible past the motor. Together with the bottom of the tank, a belly pan of sorts is formed. As a general principle, all the glasswork was insulated with rubber strips or grommets from any metal and attached using nylon screws and nylon stop-nuts. Nobody likes stress. Ducati used elastic stop-nuts everywhere they could, and this practice was continued with any new parts. My local hardware store had recently added a full line of metric fasteners that included allen cap screws and stop-nuts in stainless, no less, steel at very reasonable prices. This used to be a serious problem, but not no more. The little touches:

The curvy Italian gas cap is replaced (sorry, Syd) with an FAA approved, flush-mount that's a lot easier on chins.

The rear sets are mounted in dead-soft aluminum and folding pegs are proof against accidental grounding (don't ask). Rubberized-cork, thick gasket material lines the battery tray. The folding kick-start lever is hard to find!

Pull out the aircraft, push-button 'T' handle, and the seat slides off to reveal the regulator and relay/fuse tray. The nominal baffle in the mega improves torque (thanks, NCR) and keeps everything street legal (chuckle).

The front brake at 260mm is the largest drum set-up ever built. Yes, discs were used at the time, but they were heavier and complicated. These babies are so frightening; you can win a race when you show up in the pits. They are simple, easy to inspect (giant holes everywhere) and never suffered a hydraulic failure. The air horns are lighter than the stock (ugly) units and have enough power to be heard over the exhaust note (heh-heh). Besides, they keep it legal. The clip-ons are the adjustable-drop style (easy on the wrists) and the surgical-rubber grips have no peer. The whole of the machine compares very exactly to Paul Smart's historic Imola winner. The (wide) frame, (leading axle) forks and shocks are identical. Not so for the S and SS model. The tank is larger, but hey. Overall weight is a trim 320lbs. The GT motor is 'torque city'; durability is legend! A few words on the electrics: I am using the original key switch to operate an automotive main power relay (RadioShack). This avoids any current or voltage drops at the coils. I carefully grafted a microswitch (RadioShack again) into a horn button on the throttle housing. A switch under the 'electrics' tray allows it to either actuate the horn relay or de-activate the main power relay, i.e. a kill button. For the wiring, I chose a four-wire harness with a molded connector designed for trailer lights. The conductors are sturdy and color-coded. I like to use silver-tin for solder, and I never strip the wires with a tool. Even the smallest nick is an invitation to fracture! An aftermarket turn signal switch on the left bar operates the headlight. The center-off position kills the light and the right/left positions become the hi/lo positions (easy to flip with a thumb). It's been said that 'God lives in the details'. I may have left a few out of this story, and I hope He doesn't take any offense. Building a racer is more satisfying to me than say, trying to match original paint colors from faded magazine pictures to impress some concours judge. Engineered solutions can be elegant in their simplicity, of course all problems are trivial once they're solved, but I would never call a bevel-head Ducati simple. Trying to match the quality of the original design is all the challenge, but matching the quality of the original finish is not. For that reason alone, I made no attempt to (over)polish any of the aluminum. Besides, there would be nothing left for the next owner to do over the winter. I have yet to start the bike, mostly because the temptation to terrorize my neighborhood could be impossible to overcome. Besides, now that I'm back in practice, the Featherbed Goldstar is begging for completion. There may be some issue with club regulations, and the Langlitz people will have to let-out my old suit, but once you've smelled the castor…what can I say? A list of most of the new parts: Tommaselli: Adjustable Drop Clip-ons, Brown Rubber Grips Tunstall: Imola Tank, Seat, Fenders, License/Brake Light Sekela: Custom Fairing w/Offset Headlight, Custom Bubble Yamaha: TZ Series 260mm 4 Leading Shoe Race Brake Akront: 18in Front Rim NCR: 2 into 1 Pipes, Megaphone w/Baffle Metzler: ME33 Comp-K Tires K&N: Air Filters Megura: Clutch Lever Assembly Daytona Products: Rearsets w/Folding Pegs, Heim Joints Aircraft Spruce & Specialty: Gas Filler, 'T' Handle Fiamm: Twin Air Horns That's all the news that fits, hope you like it, Courtesy of Beau Brinker

|